These boots feature a sleek black leather exterior, providing a professional appearance.

Designed for the workplace with reinforced toe cap to protect against impacts. Designed with a rugged outsole for excellent grip and stability, these boots are suitable for construction sites, manufacturing, and other professional environments.

General information :

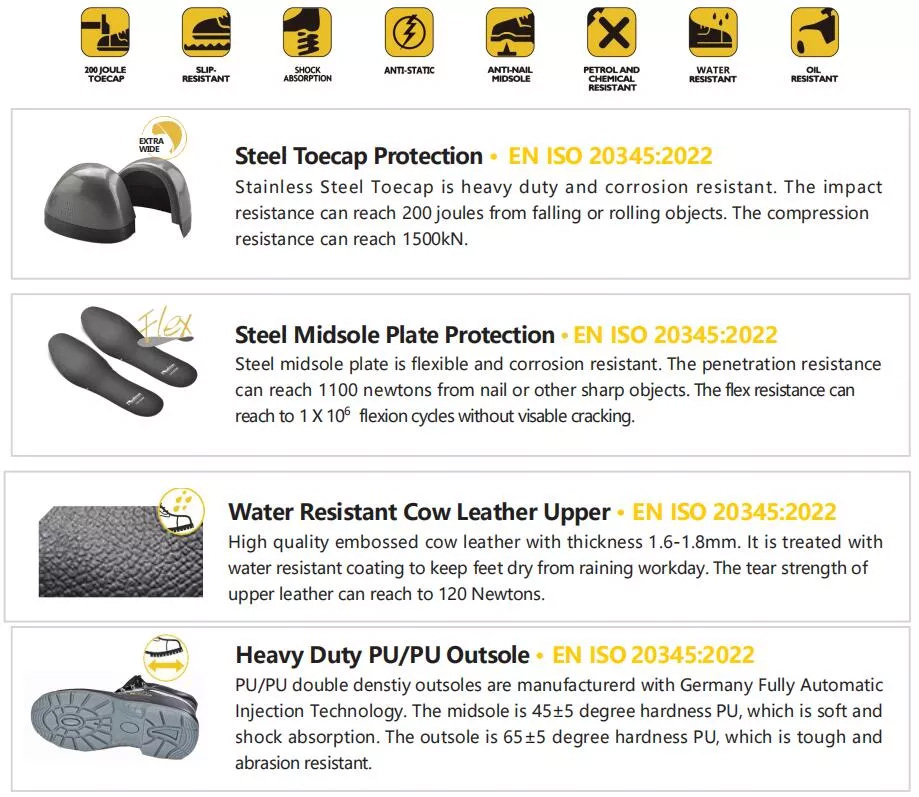

Steel Toecap Protection

Stainless steel toe cap can reach 200 joules from falling or rolling objects. It is stronger than iron toe cap.

Flex

Steel Midsole Plate Protection

Steel midsole plate, is zero-penetration resistant. It can resist 1100 newtons nail puncture from sharp objects. It is stronger and more flexible than normal iron plate.

Water Resistant Cow Leather Upper High quality cow embossed leather with thickness 1.6-1.8mm. It is treated with water resistant coating to protect feet from raining workday. Tear strength is required 10% higher than Europe test requirement, to reach longer lifespan.

Heavy Duty PU/PU Outsole The outsole is made with PU/PU dual density material. The midsole is 45±5 degree hardness PU, which is soft and shock absorption. The outsole is 65±5 degree hardness PU, which is tough and abrasion resistant. The outsole can pass SRC slip- resistant test.

Technical Details :

- Upper, Lining & Bonding Strength Test Result

Leather Tear Strength ≥ 120.0 Newtons

Leather Tensile Properties ≥ 15.0 N/mm²

Lining Tear Strength ≥ 15.0 N/mm

Bonding Strength ≥ 4.0 N/mm

- Protection with Steel Toecap (200 Joules)

Impact Resistance: Impact Energy: 200 ± 4 Joules, Internal Height Clearence ≥ 14mm Compression Resistance: Compression Force: (15 ± 0.1) KN, Internal Height Clearence ≥ 14mm

- Penetration Resistance (1100 N)

Penetration Resistance Force ≥ 1100 N

- Protection With Slip Resistant (SRC)

Test Requirement: SRA (Eurotile 2+Nal S) Forward Heel Slip ≥0.28 & Forward Flat Slip: ≥0.32

SRB (Steel Floor+Glycerine) Forward Heel Slip ≥0.13 & Forward Flat Slip: ≥0.18

Standards: EN ISO20344:2011(5.11), SRC Means both SRA & SRB requirements are fulfilled.

- Protection With Anti-Static

Test Requirement: Anti-static 100KΩ-1000MΩ, Test Voltage: 100±2 V DC, Test Period: 1 Minute

Standards: ENISO 20344:2011(5.10) Dry Humility (30±5) & Wet Humility (85±5)

- Protection Resistant to Fuel Oil

Test Requirement: Change in Volume and Change in Hardness (Outsole) is No More Than +12% (*)

Standards: ENISO 20344:2011(8.6.1)

- Sole Bonding Strength Test

- EN ISO 20344:2011, 5.2 (Between Upper & Sole)

- Average Test Result 5.8±5 (N/mm)